Before you open the door: The ultimate interior door guide for professionals.

9 chapters that are worth their weight in gold when installing interior doors.

Content 1. basic knowledge about interior doors 2. take the right measurements when installing the door 3. determine the door stop 4. what you can do wrong when installing doors 5. door fittings. What you should know about them. 6. door frames - an overview 7. door leaves - structure, surfaces, function 8. requirements for interior doors 9. legal provisions

Origin, history, components

The door has been around for over 5000 years. The first functioning interior door in Europe was found in Switzerland. While doors in Mesopotamia were purely wooden boards on a hinge in the beginning, they were perfected more and more over the course of time. There were doors made of wood, stone, bronze or a mix of different materials. The door has a high symbolic value. It visibly separates one area from another. And everyone who steps through a door enters a new space. The door indicates: Something new begins here. Doors separate living rooms from bedrooms, conference rooms from offices, the hallway from the kitchen or the bathroom from the rest of the flat. Doors can be an enormously enhancing decorative element. And the choice of door is decisive for whether or not you later feel comfortable in your own four walls.

The door components in detail are:

1. the Door leaf.

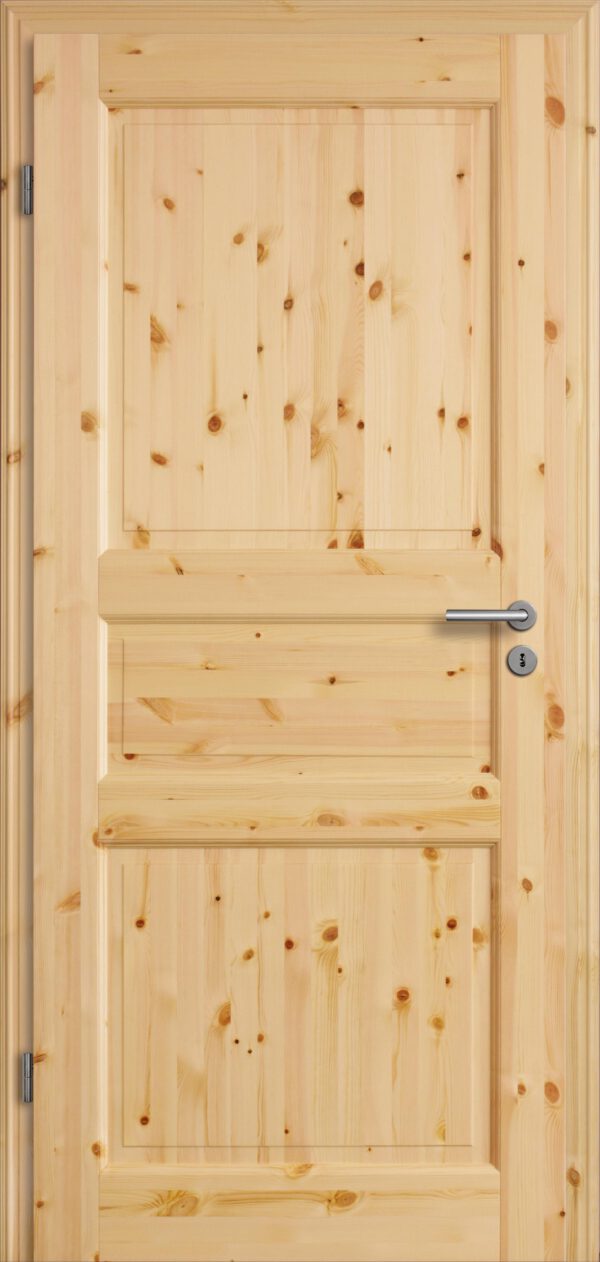

Also called door leaf. It is the movable part of the door. The door leaf can be made smoothly in one piece or as a panel door, e.g. a coffered door. In the case of swing doors, the door leaves and the door frame are movably connected by door hinges.

2. the Door frame.

The door leaf needs a part into which it can close. This is the door frame. This in turn consists of…

…the Door lintelwhich is the upper part of the door frame. This door frame carries the load of the wall above the door frame and distributes it to the posts.

…the Door frameThe frame forms the frame around the door opening. It is complemented by the door sill at the bottom. The frame consists of three parts: right, left and top. The parts are all made the same, although the lengths can of course vary. Only steel frames are usually delivered and installed in one piece.

…the Thresholdwhich in the past was usually raised and created the transition from one floor finish to the next. Today, door thresholds are often installed flush and covered by the floor covering.

…the Blind floorwhich is already installed in the shell. The blind frame protects the door from damage if the door is installed before the other work is finished. The blind frame acts as a plaster moulding. Only with a blind frame is it possible to install the finished floor after all work has been completed.

…the Aperturewhich is usually integrated into the frame. It is the visible part of the door piece and is designed as a decorative panel.

3. the Door rebate.

There are two options for single-action doors: Either the door leaf is straight. In this case it is called blunt. Or it is rebated at the edges with a step. This is called stepped. Doors that need to keep out a lot of sound or heat have a double or triple rebate with a corresponding number of sealing profiles, i.e. up to four. This makes it possible to achieve high sound and heat insulation values.

4. the Door seal.

It runs in one piece around the door leaf in the frame. The door seal is usually a rubber or plastic seal. It ensures a seamless connection between the door leaf and the frame. The seal is of particular importance with regard to sound and heat insulation. It should function without joints and be correspondingly hard-wearing and durable.

An overview of the different interior doors

Basically, there are three types of interior doors. A rough distinction is made:

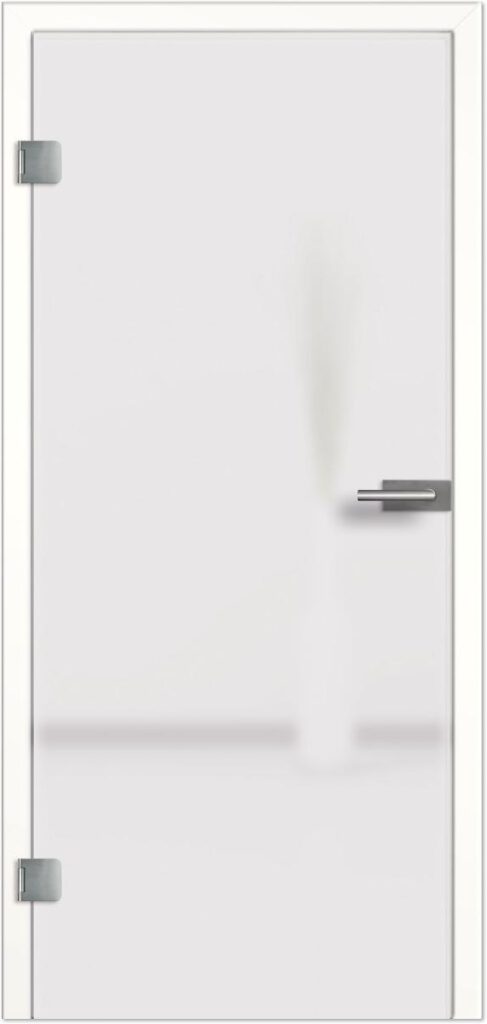

As a further alternative All-glass doors used. They are usually made without a frame from a single sheet of glass. They are ideal where there is high humidity or where you want to bring as much light as possible into the room.

In addition to the materials, the construction and surfaces of interior doors also differ:

The classic: the smooth interior doors.

Smooth interior doors are characterised by the uniform, smooth surfaces created from CPL (Continuous Pressed Laminates), HPL (High-Pressure Laminates), lacquer or real wood veneer. The door is covered on both sides with a panel containing either a lightweight honeycomb core or solid chipboard. Solid chipboard provides maximum stability and noise insulation, but is also correspondingly heavier and more expensive.

The following surfaces are available for room or interior doors CPL (Continuous Pressed Laminates) and HPL (High-Pressure Laminates) are used, which are particularly good-natured and hard-wearing. They don't scratch so quickly, can withstand the odd bump and keep their shape. No matter what comes.

The basic rule before installing a door is: measure, measure, measure. Because even the best professional cannot install a door with the wrong or inaccurate measurements. We are dealing with two different situations.

Situation 1:

The door is installed completely new, e.g. in a new house or in a new flat. Now it is important to clarify a few things in advance:

- Which floor covering is intended for the room in question and what is its thickness?

- Will the wall still be plastered? Has the thickness of the plaster already been taken into account?

- Will there still be tiles, wallpaper or structural plaster on the walls and do they have to be considered separately at trade fairs?

This gives you the exact measurements when measuring the door opening:

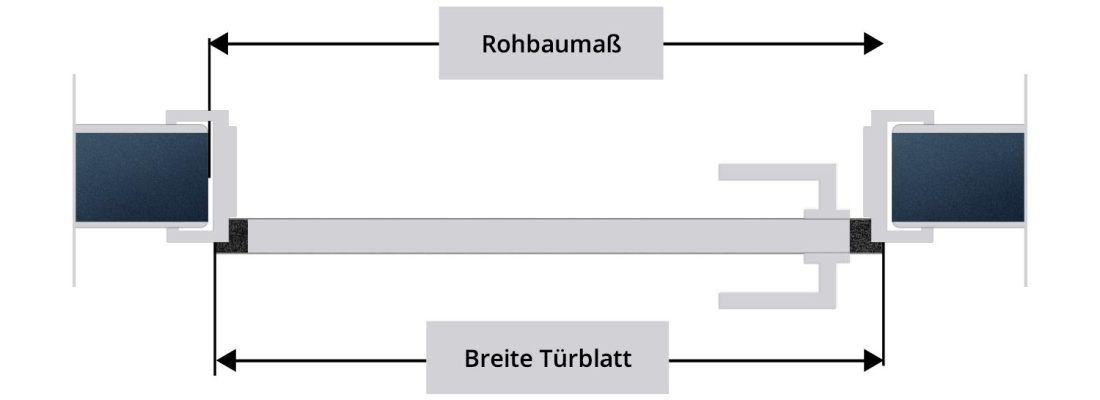

It is essential that you distinguish between the shell dimension and the door leaf dimension. When you are standing in front of the open shell opening, you must specify the shell dimension. You determine the shell dimensions for an interior door by measuring the height and width of the shell opening to the centimetre in three places and doing the same with the wall thickness. Measure the height vertically from the upper edge of the finished floor to the lower edge of the ceiling. When doing this, do not hold the folding rule or tape measure at an angle.

And be careful! If the floor is not yet in place, you must subtract the height of the finished floor from the total height. You should do this at least twice, preferably three times, in order to determine any deviations in the unfinished floor. In the width, measure the shell opening from the left edge to the right edge in three different places to detect inaccuracies in the shell here as well. You work with the smallest of the three values in case there are deviations in the values. Then determine the wall thickness. Again, this is best done at three different heights. The wall thickness is measured as the thickness of the wall and must include all applied materials such as plaster or tiles. If these materials have not yet been applied, the expected thickness must be added to the measurement result. For different wall thicknesses, many frames can now be individually adjusted to the values.

Situation 2:

There is already a built-in door or frame and the door or door and frame are only to be replaced. This makes the measurement much easier. Because now you only have to take the measurements of the existing door leaf and the existing frame.

To do this, you must measure the height and width of the door leaf on the outside of the rebate. This is the side that abuts the frame. Make sure that the folding rule or tape measure is absolutely vertical or absolutely horizontal.

And to determine the correct wall thickness, first measure the depth of the complete frame (consisting of lining board and cladding) and then subtract the thickness of the frame cladding resting on the wall from the total depth. This will give you an accurate result for the real wall thickness.

The DIN standard for interior doors and frames.

Fortunately, door elements are standardised nowadays so that the various elements fit together. The standard dimensions for interior doors refer back to various DIN (German Institute for Standardisation) standards. To be more precise, DIN 18100, DIN 18101 and DIN 4172.

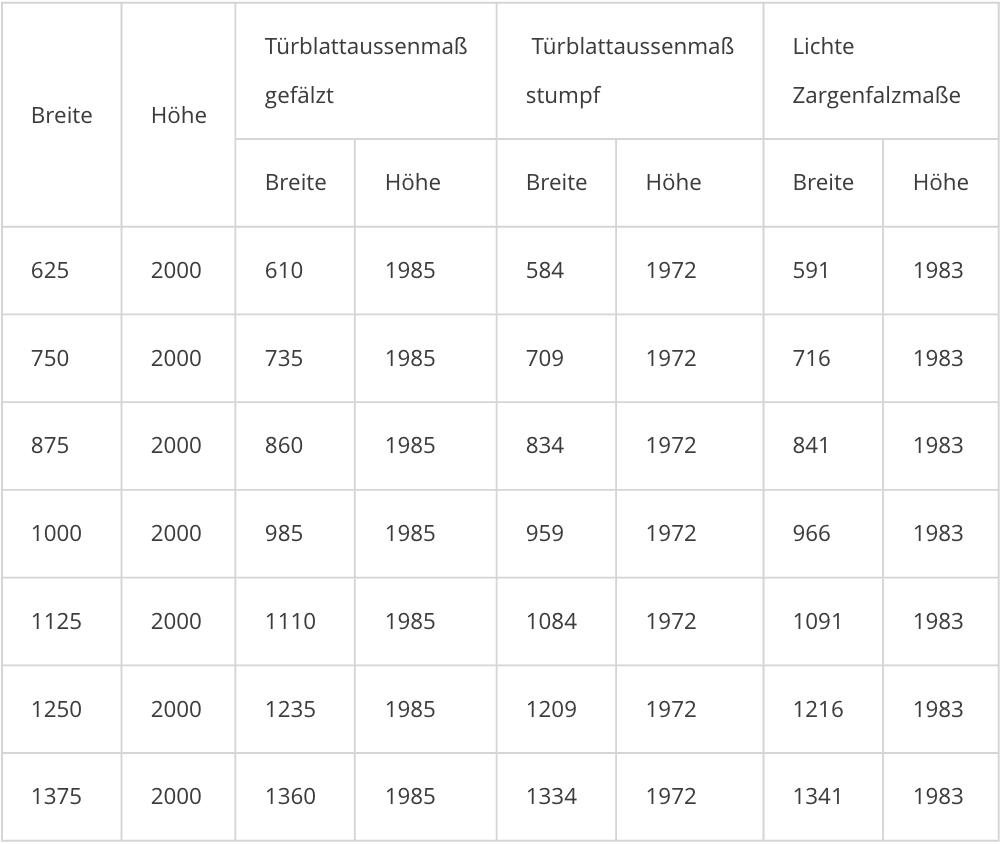

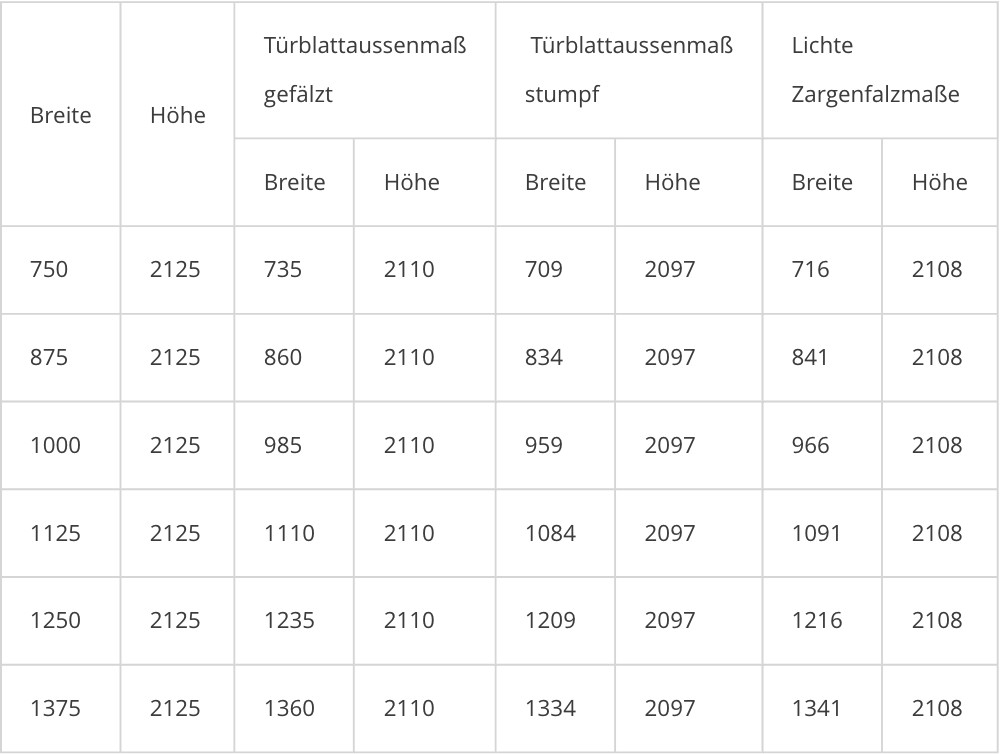

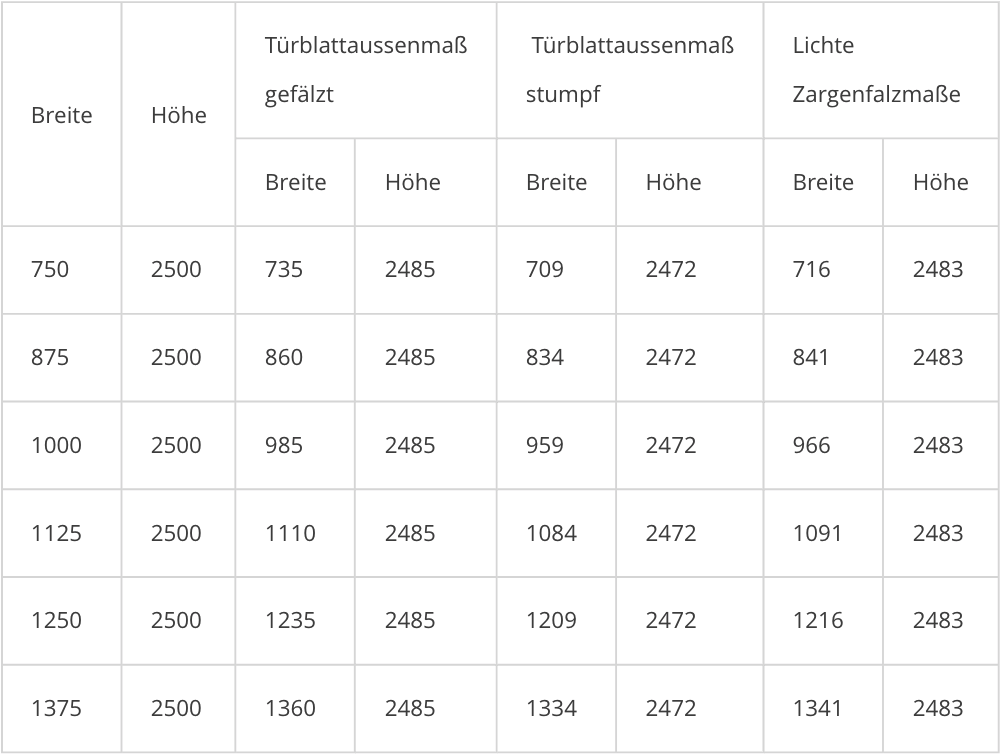

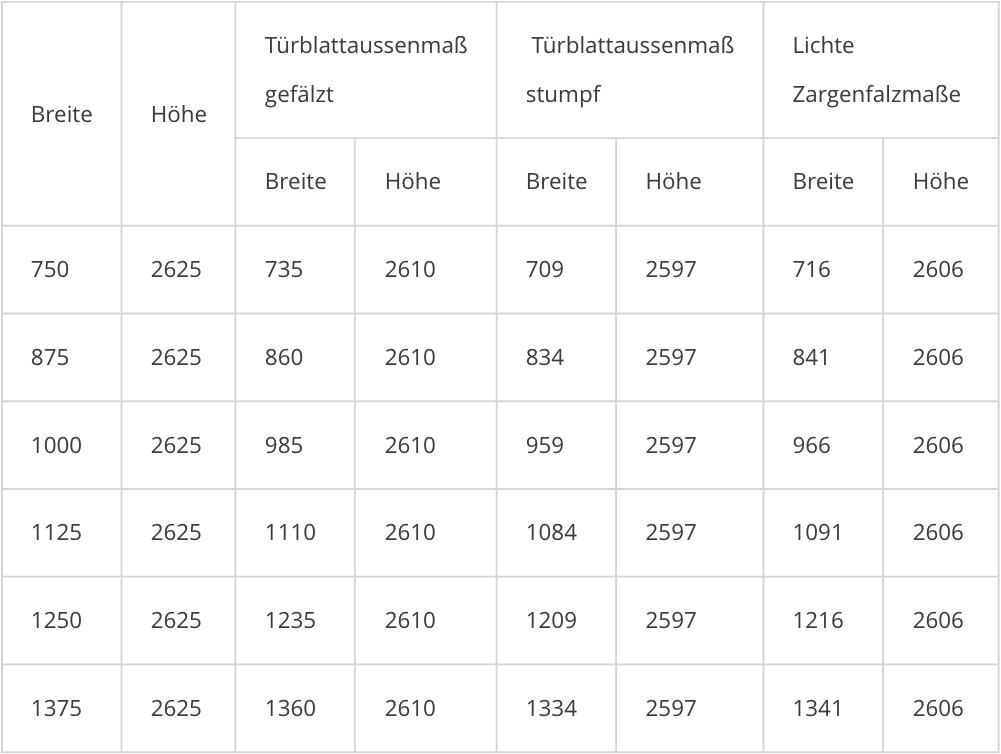

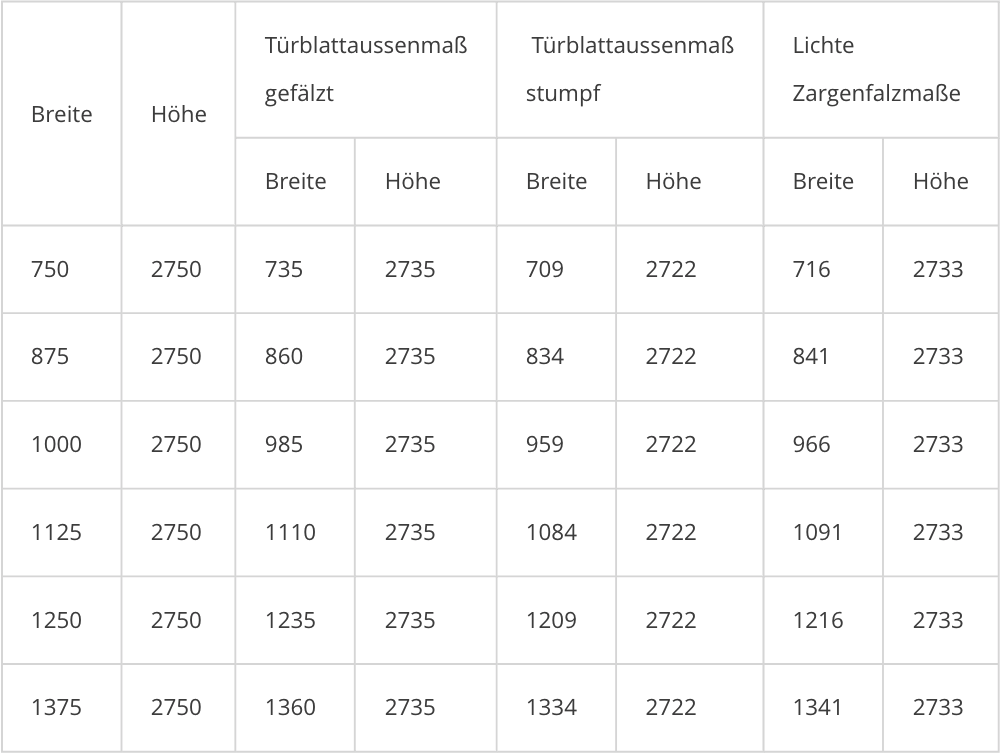

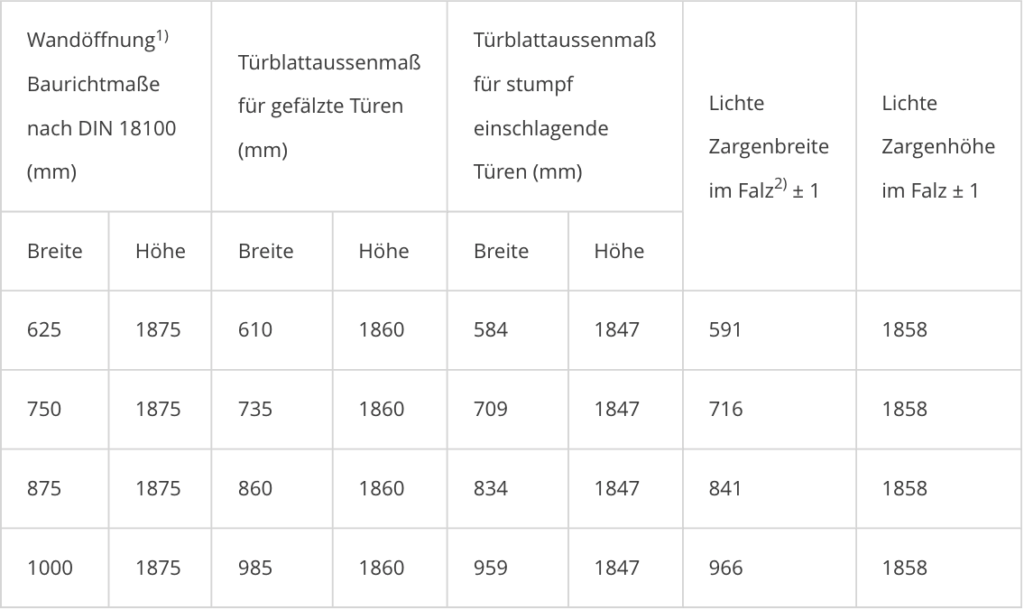

Here is an overview of all dimensions for interior doors.

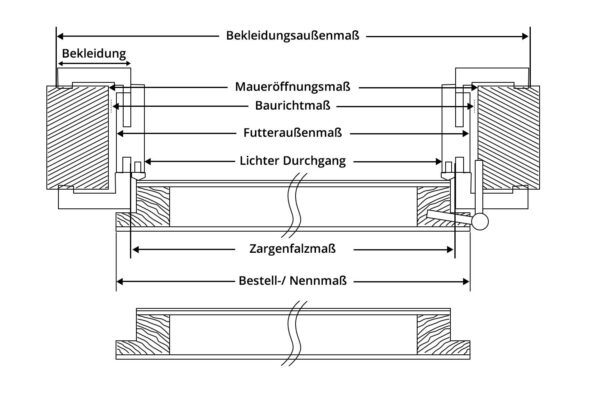

How to measure frames correctly.

No door without a door frame. The dimension of the frame is determined by the dimension of the wall opening and the dimensions of the door leaf. Here is an overview of the interaction of the various dimensions:

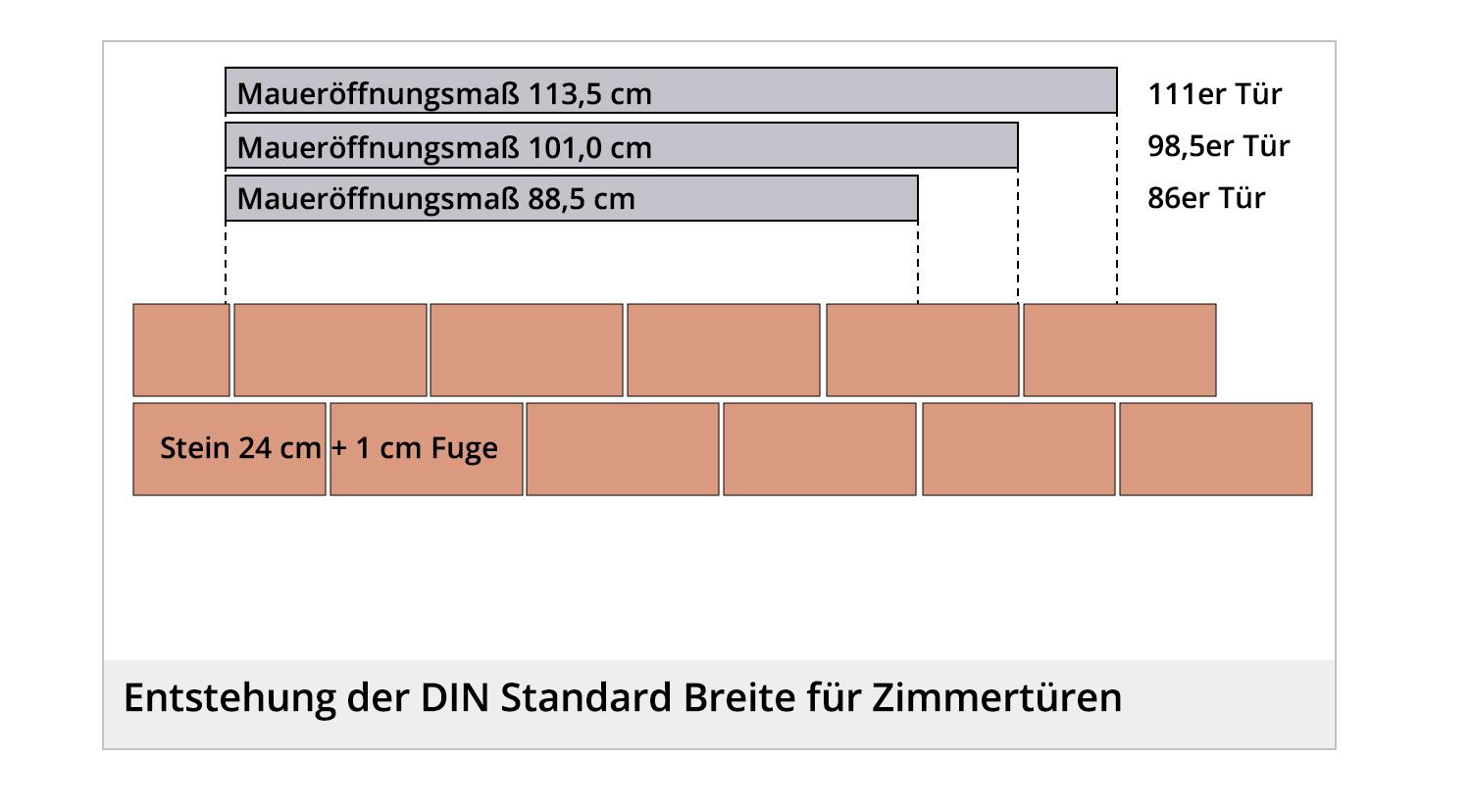

Where do the DIN dimensions for interior doors come from?

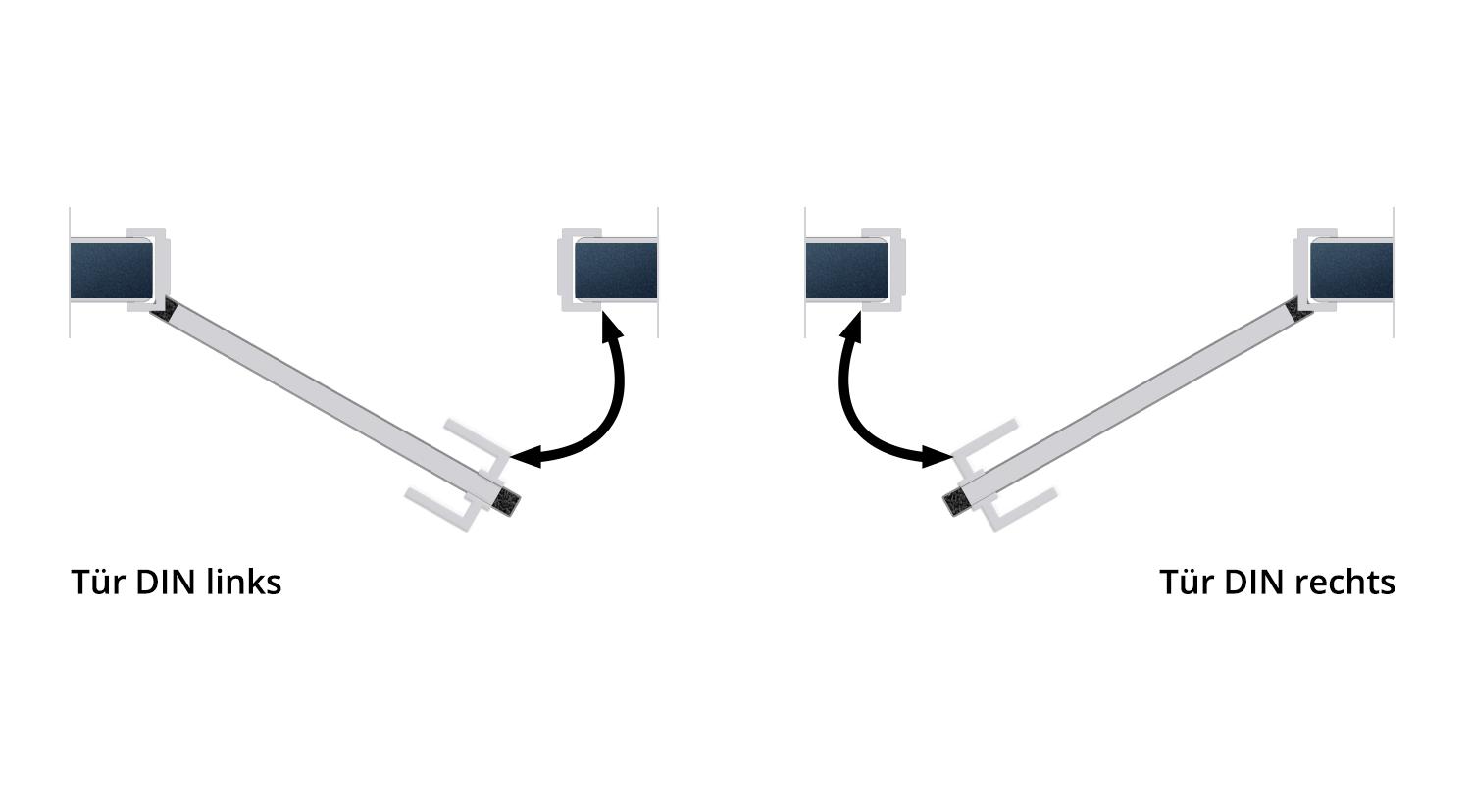

Doors can be opened either to the right or to the left. And they open either inwards or outwards. So what do you have to look out for when deciding on a particular door hinge?

Basically, you have to start from the room into which the door is opened. So if the room door opens outwards, it can be the hallway, if it opens inwards, the bedroom, living room or dining room.

It is important that the door opens to the nearest corner of the room.

If the door opens inwards and has the DIN right-hand stop, the hinges and hinges must be visible on the right from the room into which the door opens.

If the door opens inwards and has the DIN left stop, the hinges and hinges of the room into which the door opens must be visible on the left.

The same applies to doors that open outwards, in which case you must look at the door from the outside and the hinges and hinges must be visible on the left-hand side for the DiN left-hand stop and on the right-hand side for the DIN right-hand stop.

Even with precise planning and careful selection of interior doors, you can get a lot wrong during installation. And this even happens to professionals. It is therefore good to remind yourself of what is important.

Measure, measure and measure again.

The best door cannot be installed by the best craftsman if it is incorrectly dimensioned because it has simply been measured sloppily. Even a few millimetres can cause the door to jam or not open or close at all. Therefore, here is a small guide in 9 steps.

Error 1: Inaccurate measurements in width.

Measure the width of the door opening in at least two, preferably three different places. If there are deviations, then the wider point is decisive for the width of the front door or the frame. This is because the manufacturer deducts the so-called "installation clearance" per se from this measurement. This then leads to a smaller final door dimension, so that the installation can be carried out without any problems.

Error 2: Inaccurate measurements at altitude.

Measure the height of the door opening. Measure from the threshold to the top of the door (ATTENTION! take into account any floor coverings that may be installed later). Here, too, it is important to measure in at least two places, and preferably in three. If the threshold has not yet been installed, its dimensions must be taken into account.

Error 3: Not to determine the opening direction in advance.

You wouldn't think it, but it happens time and again that the opening direction of the door has not been defined beforehand. But of course you have to define the opening direction before ordering a door. Should the door open inwards or outwards, to the right or to the left. It is best to enter the opening direction and the opening radius of the door in the floor plan to see which side and which direction is the optimal one.

Error 4: Installing the frame at an angle

The door frame must be installed absolutely straight and precisely. Even a small angle of inclination of 1° can lead to a lack of tightness, heat loss and sound insulation. The door frame is firmly anchored in the wall opening and adjusted absolutely straight before installation. Only then can the door leaf be hung without problems.

Error 5: The door is not completely sealed.

The sealing of a door is crucial for thermal and sound insulation. Unfortunately, mistakes are often made when sealing. Here are the most important ones:

Lack of a permanently elastic seal between the frame and the wall. Instead, foam is only used in excess. But the foam neither keeps out the sound nor the heat in the room. In times when many houses are no longer heated in all rooms, the heat-insulating properties of interior doors are all the more important.

Floor seal too short. If it is necessary to install a floor seal for thermal insulation and soundproofing, then this must always be In any case, they must reach under the door frame. Otherwise sound insulation gaps and thermal bridges will form.

Error 6: Installation at the wrong time

Time and again, the doors are installed when everything else is far from finished. This then leads to scratches and damage from the other trades. The doors should be installed at the end of the construction work and not right at the beginning.

Error 7: Incorrect storage before installation

In construction, materials do not arrive "just in time", but delivered goods sometimes have to wait a few weeks on the construction site before they can be installed. If you simply stack your doors somewhere and expose them to the sun or even frost, you should not be surprised if the good pieces are completely warped afterwards. For this reason, doors should be stored in a transport safety frame until installation and, if possible, in such a way that they are not exposed to sunlight, moisture or frost.

Doors have to open and close. And since they don't do this by themselves, doors need door fittings. And these are a science in themselves. They come in a wide variety of materials, colours, shapes and styles.

Let's look at the materials:

Door fittings made of plastic. They are characterised by an enormous variety of colours and shapes. Plastic fittings are hygienic, easy to clean, simple to change and relatively inexpensive. Unfortunately, they become brittle and exposed to UV radiation and do not have a very long life overall. But they are so cheap that you can replace them every few years. That is why you often find plastic door fittings in doctors' surgeries, care facilities, government offices or other places where there is a lot of visitor traffic.

Aluminium door fittings. Aluminium fittings are robust, light and easy to clean. They are anodised and extremely durable thanks to the protective coating on the metal. There is a wide choice of colours and you can choose between matt and glossy. Those who think practically choose aluminium.

Stainless steel door fittings. They not only look elegant, but are also very durable. However, stainless steel fittings must be polished from time to time so that they do not lose their shine. Rust is not an issue because the fittings are all made of a rust-resistant chrome-nickel steel alloy. Scratches and other mechanical impacts are hardly to be feared on them. They are as hard as steel.

Brass door fittings. Simply beautiful and of very high quality. But beware, brass needs intensive care, otherwise a patina will form and the fittings will lose their shine. If you want to present brass fittings, you have to clean them thoroughly on a regular basis and invest time. If you don't want to do that, it's better to do without brass. After all, there are also stainless steel fittings in brass look.

Handle, fabric handle or knob?

In Germany, we love our door handles. Door handles come in all sizes, styles and colours. They are so easy to use that even small children or pet dogs quickly learn to press the handle and open the door. Which is why it is also fashionable to install a lockable version with a box lock on interior doors.

Internationally, the rotating door knob enjoys great popularity. As a rule, it is turned to the right and the door opens. Big advantage: small children or dogs have considerably more difficulty with the knob, so in case of doubt you can save yourself the additional lock.

There is also the push handle. They can be used to push open unlocked doors or double doors. For example, for visitors who like to make a grand entrance. Since the opening mechanism is omitted with this variant, it cannot be broken either.

By the way: all door handles, whether handle, fabric handle or knob, are standardised according to DIN and always have a height of 105 cm. Which is why we can unerringly reach for the door handle even at night without missing it.

Handle sets. No door opens without them.

Not all door frames are the same and there is also a choice of different frames for interior doors. These are:

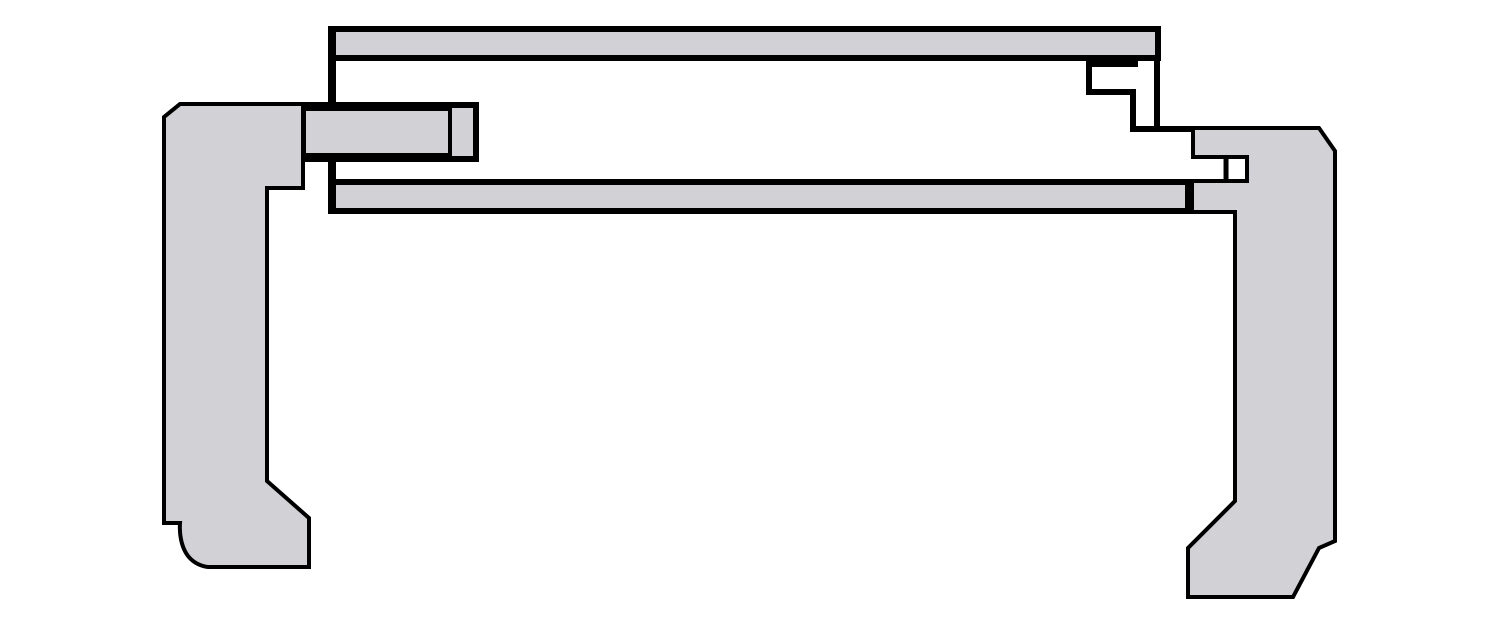

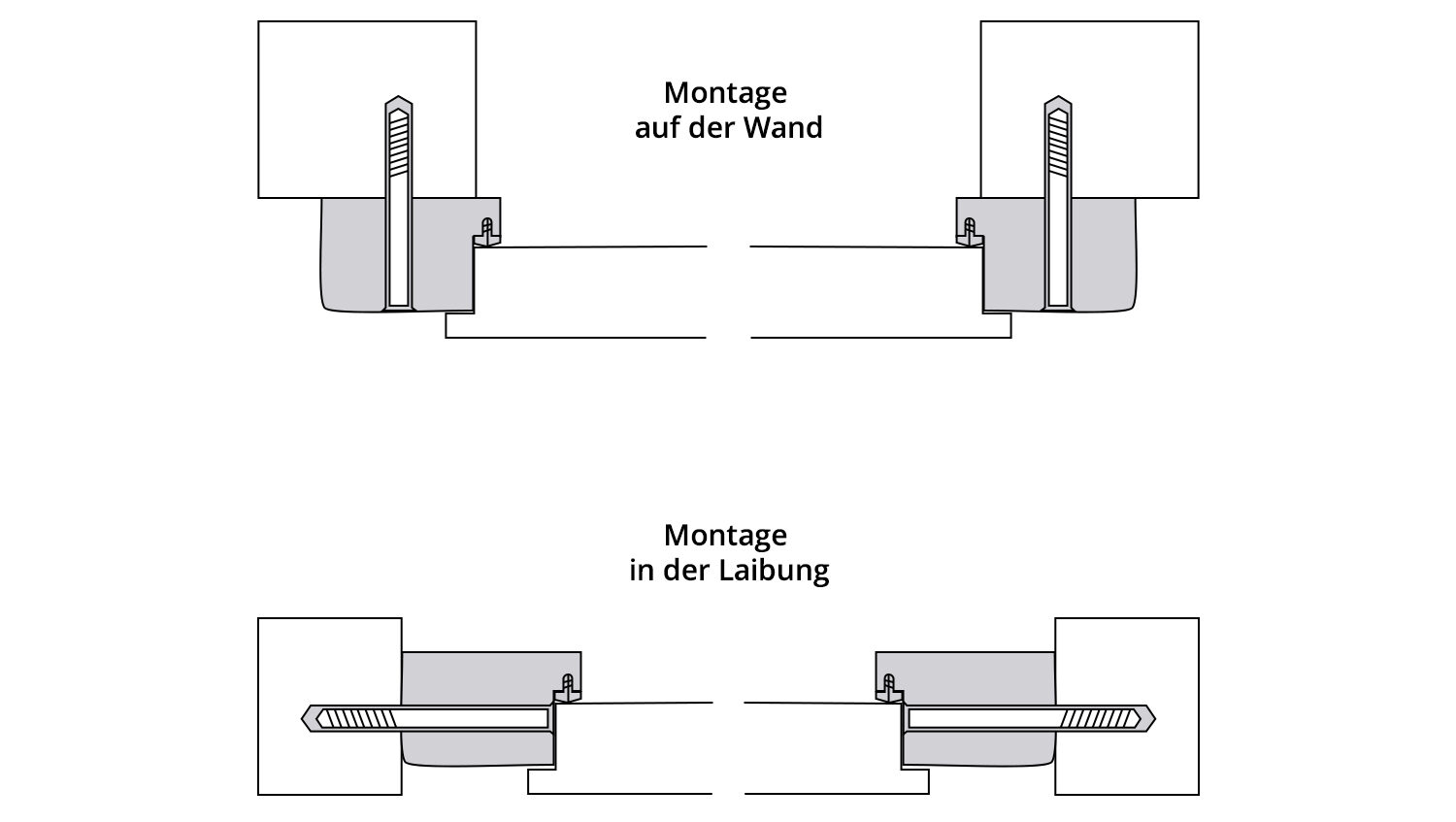

The surround frame. It encloses the wall reveal. There are frame frames in wood as well as in steel or aluminium.

- The block frame. It is inserted inside the wall opening and reduces the opening. Since it does not enclose the wall reveal, there is no recess between the wall and the frame.

- The frame. It is placed in front of the wall opening and can be easily doweled. It is particularly suitable for small wall openings and can be used for very thick walls as well as for very narrow wall thicknesses.

- The inner door with honeycomb insert. Not necessarily recommended because the interior consists of cardboard honeycombs that offer virtually no sound insulation and no thermal insulation.

- The tubular chip strip door leaf consists of tubular chip strips at its core. This saves material and weight and of course costs. However, it is also hardly recommended if you expect more than just decorative properties from your interior door.

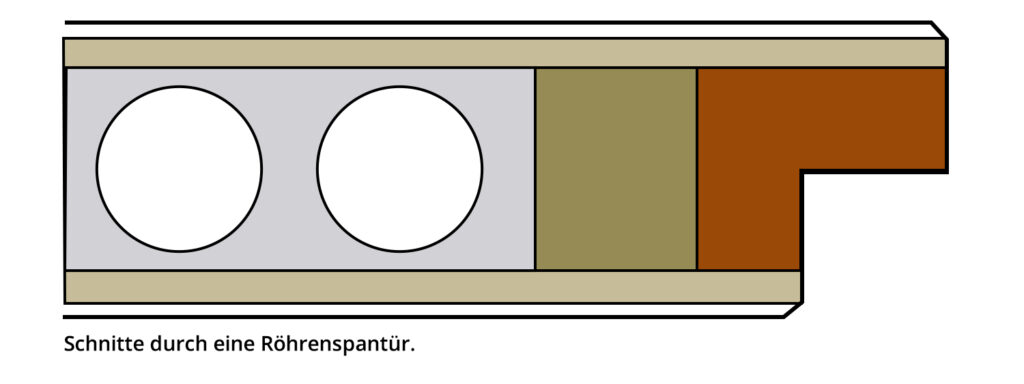

- The tubular chipboard door leaf. The core of the door leaf consists of a chipboard into which tubes have been milled. The air chambers are primarily used for thermal insulation. Such a tubular chip door leaf consists of five elements:2 cover plates 1 hardboard panel with tubes that serves as door panel infill 2 edge elements

- The solid chipboard door leaf. It is used everywhere where noise should stay outside. So in schools, hotels, hospitals or for particularly noise-sensitive private individuals who absolutely do not want to hear anything from their children. With a single-layer or three-layer solid chipboard panel as the filling, this door leaf achieves sound insulation class 1. No wonder with a door leaf thickness of 41 or 50 millimetres.

Door leaves. The surfaces.

There are an infinite number of finishes for door leaves. Here is a summary of the most common looks and finishes.

White door leaves.

Are either lacquered or have a CPL top layer. The white interior doors are immortal classics and white is by far the most popular door colour.

The requirements for interior doors are becoming more stringent every year. There are countless standards and rules that specify how an interior door must be built, how to install it and which functions are indispensable.

Many requirements are now defined by European standards and rules and there is also a CE marking for interior doors.Here is the necessary information: https://www.ift-rosenheim.de/documents/ 10180/1683723/PI190440/537ac288-e343-1962-204c-2bb0e1b1a21d

Here are some requirements for interior doors:

The small door leaf dimension is 610 × 1860 mm (DIN68706-1)

The smallest door frame is 625 × 1875 mm (DIN 68706-2) according to the building regulation. These are the smallest door dimensions for the private sector.

Special regulations exist for offices, public buildings, escape doors, etc.

Doors that are to be designed barrier-free must meet the following requirements according to DIN 180204 for flats and according to DIN 18025 for public areas and workplaces:

- clear width 90 cm (with wheelchair)

- clear width 80 cm (without wheelchair)

- Clearance height 210 cm

- Handle, operating devices 85 cm high

- without threshold (maximum 2 cm if technically unavoidable)- must never open inwards into small rooms.

- must never open towards the staircase.

- Maximum tolerances for horizontal or vertical installation up to 3 m element length 1.5 mm.

- For the installation of steel frames, the guideline of the

"Industrial Association Doors Doors Frames" under www.ttz-online.de

There are more and more rules, standards and laws. Here are a few of the most important legal provisions without claiming to be exhaustive. In this article, we only want to point out a few sources from which you can inform yourself about the legal provisions.

Provisions at the federal level:

Especially in workplaces, you can't just install nice or practical doors; you have to comply with an extensive body of legislation. Here are the most important regulations for doors in workplaces:

> Click here for ASR 1.7 "Doors and Gates

In addition, there are numerous regulations at Land level that must be taken into account. Here are a few exemplary websites where you can get information:

Standards www.beuth.de

Model Building Code www.is-argebau.de

Building regulations of the Länder www.bauordnungen.de or pages of the respective state ministries

Sample special building regulations www.is-argebau.de

Conclusion:

Interior doors and room doors are a small world in themselves. And even professionals can learn something new every day. At Capital Baustoffe, you not only get a large selection of interior and room doors, but also the necessary expert advice that will not leave you alone with any door problem.